Essential RCD Testing: Your Guide to Safe Electrical Circuits

Hey there, folks! When it comes to keeping your home safe, Residual Current Devices (RCDs) are like the trusty watchdogs of your electrical system. These little heroes spring into action, cutting off power at the first sign of trouble, and can prevent nasty shocks or even fires. But just like any good watchdog, they need a regular check-up to make sure they’re on their game. That’s where RCD testing steps in. It’s not just a good idea—it’s a lifesaver. Let’s dive into the essentials, so you can keep your circuits safe and sound.

What is RCD Testing?

RCD testing is all about making sure our electrical systems are safe and sound. This process checks Residual Current Devices (RCDs) to ensure they’re working properly. These devices are like the unsung heroes of our homes, stepping in to protect us from electric shocks and potential fires. Regular testing is crucial because it keeps these devices in tip-top shape, providing a vital layer of protection for any electrical setup.

The Basics of RCD Testing

Now, let’s dive into the nitty-gritty of RCD testing. It’s not just a legal requirement—it’s a safety must-have. Think of RCDs as the guardians of your electrical circuits. They’re designed to prevent nasty surprises like electrocution. By testing them regularly, we’re making sure they’re ready to spring into action when needed. It’s like giving your safety net a little check-up to ensure it’s ready to catch you if you fall.

The Functionality of RCDs

So, how do these RCDs work their magic? They’re constantly on the lookout, monitoring electrical currents. Imagine them as vigilant watchdogs, ready to cut off power at the first sign of trouble. They’re installed in circuits with both live and neutral wires, which usually balance each other out. But if something goes awry, causing an imbalance, the RCD jumps into action. It trips, breaks the circuit, and stops potential hazards in their tracks. This quick response is key to keeping things safe and sound.

The Significance of RCD Testing

RCD testing plays a crucial role in ensuring electrical safety and compliance. It’s not just a technical requirement, but a safeguard for your home and loved ones.

Legal Obligations and Safety Norms

In many places like Australia, the UK, and New Zealand, RCD testing isn’t just a suggestion—it’s the law. These rules are there to make sure that all electrical circuits and appliances meet tough safety standards. By sticking to regulations like BS 7671, you’re certifying that your circuit is safe to use. Regular RCD testing shows you’re on top of these safety norms and legal duties, giving you peace of mind that everything’s running safely and soundly.

Preventing Electrical Dangers

When it comes to stopping electrical accidents and injuries, regular RCD testing is a game-changer. RCDs are like the unsung heroes of your electrical system; they cut off the power if they sense something’s off with the current. This quick action is key to avoiding potential hazards.

Testing regularly ensures your RCDs are up to the task. It also helps spot if you’ve got the wrong type of RCD or if there are hidden faults in your appliances or circuits. Catching these issues early means you’re preventing electrical dangers before they even have a chance to happen.

Understanding Different RCD Types

Residual Current Devices (RCDs) are essential for electrical safety, coming in various types to meet different needs and requirements. Let’s dive into the types of RCDs and their unique roles in keeping your electrical systems safe.

Exploring Various RCDs

Insight into Type AC, Type A, Type F, and Type B

RCDs are like the unsung heroes of electrical safety, each type designed for specific tasks. Type AC RCDs are your go-to for handling standard alternating current (AC) circuits. They’re perfect for everyday household and commercial settings where only AC currents are at play. Think of them as the dependable workhorse for your basic electrical safety needs.

Now, if you’re dealing with environments where electronic devices might sneak in some direct current (DC) into the mix, Type A RCDs are your best bet. They offer that extra layer of protection by catching both AC and pulsating DC currents. It’s like having a vigilant guard on duty.

When it comes to specialized setups, Type F RCDs step up to the plate. They’re crafted for circuits with variable frequency drives, often seen in industrial scenarios. These RCDs are adept at managing the quirks of such systems, ensuring everything runs smoothly.

And then there’s the Type B RCDs, the big guns for situations involving smooth DC residual currents. Think photovoltaic installations or electric vehicle charging stations. Their ability to detect a wide range of current types makes them indispensable for comprehensive protection.

Fixed, Socket-Outlet, and Portable RCDs

RCDs aren’t just about what they can detect; they’re also about how they fit into your life. Fixed RCDs are like the steadfast guardians of your electrical panels, offering protection to entire circuits. They ensure that all connected devices and appliances are safe from electrical mishaps.

On the flip side, Socket-outlet RCDs are the localized protectors. Integrated directly into power outlets, they’re perfect for individual appliances. It’s like having a bodyguard for each gadget, without the need to overhaul your entire circuit.

For those on-the-go needs, Portable RCDs are your flexible friends. These plug-in devices can be used wherever you need them, providing instant protection. They’re ideal for outdoor adventures or temporary setups, ensuring safety without tying you down to permanent installations.

Each type of RCD plays a vital role in maintaining electrical safety, catering to different needs and environments. It’s all about having the right tool for the job, ensuring peace of mind wherever you are.

Step-by-Step RCD Testing Process

Let’s walk through the essential steps of RCD testing, ensuring your electrical systems are safe and sound. From a keen visual inspection to interpreting test results, each phase plays a vital role in maintaining electrical safety.

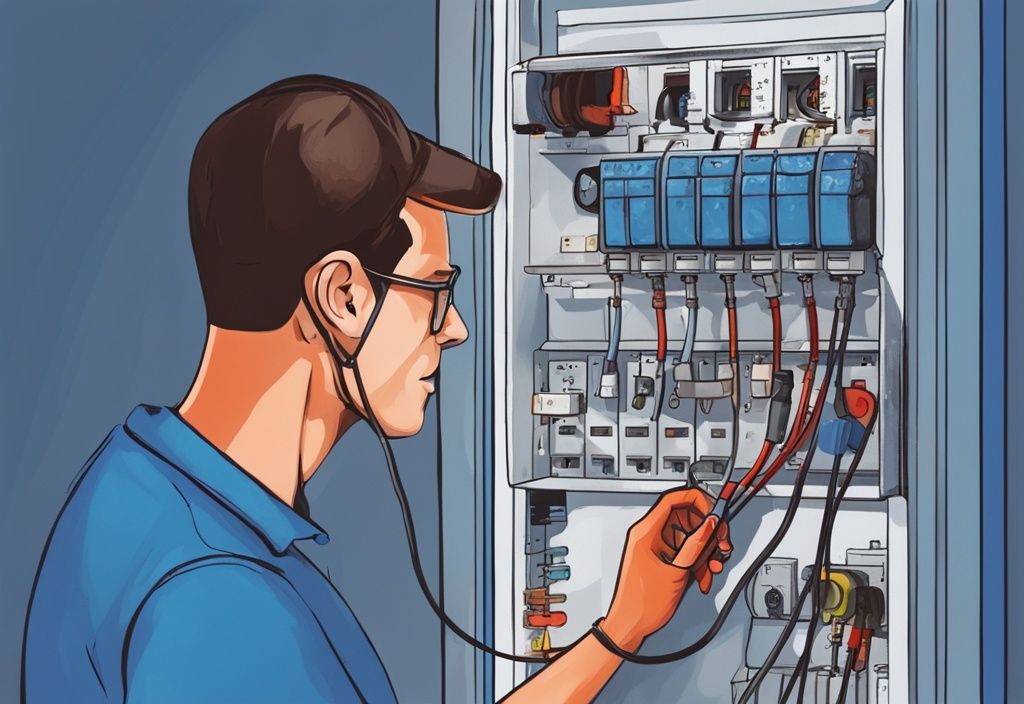

Visual Inspection

Before getting into the nitty-gritty of RCD testing, start with a good old-fashioned visual inspection. This is where you give your Residual Current Devices (RCDs) a once-over, checking for any visible damage or wear. Think of it like checking your car’s tires before a road trip. Look out for cracks, discoloration, or any odd deformities that could spell trouble. Also, make sure all connections are tight and free from corrosion. If you’re considering a sustainable option for cooling your home, explore our guide on solar powered air conditioning to see how it can make a difference. This step is like laying the groundwork, setting you up for more detailed testing later on.

Effective Testing Methods

Push Button Test

The push button test is your go-to for regular RCD maintenance. It’s as simple as pressing a button, literally. By hitting the test button on the RCD, you simulate a fault, and if all’s well, the RCD should trip. It’s a bit like giving your smoke alarm a quick test. Doing this every three months keeps your RCD in tip-top shape, ready to protect when needed. Plus, it’s a task you can handle without calling in the pros.

RCD Trip Time Test

Now, if you’re after a more thorough check-up, the RCD trip time test is where it’s at. This one measures how fast the RCD reacts during a fault, and it’s a bit more complex. You’ll want a professional electrician for this, as it requires some expertise. The goal is to ensure the RCD trips within the acceptable range, usually between 200 and 300 milliseconds. This test, done annually, is like getting a detailed health report for your RCD, confirming it’s ready to tackle electrical hazards.

Interpreting Test Results

Once you’ve run the tests, understanding the results is key to keeping things safe. If an RCD doesn’t pass the push button or trip time test, it’s time for a replacement. Don’t wait—it’s like ignoring a flat tire. If the RCD trips without reason, fails during testing, or won’t reset, regular professional checks are a smart move. Ensuring your test results align with regulations is crucial for maintaining safe and reliable circuits. This proactive approach helps you dodge electrical risks and stay compliant with safety standards.

Compliance and Regulations

Understanding the compliance and regulations around RCD testing is like knowing the rules of the road before you drive. It’s all about ensuring safety and efficiency in your electrical systems, which is crucial for both peace of mind and legal obligations.

BS 7671 and Other Relevant Standards

BS 7671, or the IET Wiring Regulations, is your go-to guide for electrical installations in the UK. Think of it as the rulebook that keeps your wiring safe and sound. It’s essential for making sure that Residual Current Devices (RCDs) do their job—protecting against electrical hazards. By sticking to these standards, you’re not just following the law; you’re making sure your home is safe from shocks, fires, and other nasty surprises. It’s like having a safety net that keeps everyone secure.

Record Keeping and Documentation

Keeping records of all your RCD tests is like keeping a diary of your electrical system’s health. Each entry should note the date, the results, and any fixes you had to make. This isn’t just about ticking a box for compliance—it’s about making troubleshooting easier and ensuring everything runs smoothly. With detailed records, you can quickly spot any issues and address them before they become bigger problems. Plus, having that historical account is a lifesaver during inspections or audits. It’s all about showing you’re committed to a safe environment.

FAQs About RCD Testing

RCD testing is a crucial part of maintaining electrical safety in your home. Below, we delve into some common questions about this important process, offering practical advice and insights.

How often should RCD testing be conducted?

Think of the push button test like checking the oil in your car—quick and easy. You should do it every three months. For a deeper dive, much like taking your car in for a full service, an annual RCD trip time test by a professional electrician is a must. This ensures everything is working safely and up to code.

Can I perform RCD testing myself?

Absolutely, you can handle the push button test yourself. It’s as simple as flipping a light switch. But for the trip time test, you’ll need to call in the pros. They have the right tools and know-how to get it done safely.

What should I do if my RCD fails a test?

If your RCD doesn’t pass the test, it’s like a smoke alarm that doesn’t beep—time for a replacement. Don’t wait around. Also, if it trips for no clear reason or won’t reset, get an electrician to take a closer look.

Why is it important to keep records of RCD tests?

Keeping records of your RCD tests is like having a service history for your car. It shows compliance with safety standards and helps troubleshoot any issues down the road. Plus, it keeps your home safe and sound.

Conclusion

Keeping your electrical systems safe is a top priority, and RCD testing is a key player in making that happen. Regularly testing Residual Current Devices helps both homeowners and businesses dodge potential electrical hazards. This proactive step not only shields folks from electric shocks and fires but also keeps you on the right side of the law.

Think of regular maintenance and testing of RCDs as your safety net against unexpected accidents. These nifty devices are designed to cut off power in a flash if there’s an electrical fault. So, it’s crucial to check their functionality every now and then. By doing this, you can rest easy knowing your electrical systems are running safely and smoothly.

On top of that, keeping detailed records of all your RCD tests is a smart move. These records are your proof of compliance with safety regulations and can be a lifesaver when it comes to troubleshooting and future maintenance. Accurate documentation means any hiccups can be sorted out quickly, boosting the overall safety and reliability of your electrical installations.

Post Comment